Automation for home improvement retailer: Leroy Merlin opts for AGVs from STILL!

Leroy Merlin

Sector: French retailer and chain of home improvement stores. Approx. 100,000 employees, nearly 400 stores in 12 countries.

Challenge: 72,000 m2 warehouse area, daily handling volume of around 3,600 pallets or 70,000 packages.

Solution: Analysis, planning and implementation of a new warehouse concept. Nearly half the surface area was automated. System integration inc. warehouse management system (WMS), warehouse control system (WCS).

Products: Automated STILL EXV iGo systems high lift pallet trucks, automated STILL MX-X iGo systems very narrow aisle trucks, warehouse control system (WCS)

Leroy Merlin is a French retailer and chain of home improvement stores. Its Réau site in the Seine-et-Marne department covers an area of over 72,000 m2, half of which has now been automated. STILL has been Leroy Merlin’s intralogistics partner for over 15 years and has contributed a total of 27 AGVs (Automated Guided Vehicles) to one of its recent projects in order to improve the quality of picking, reduce errors and shorten lead times.

The Réau logistics site is located in Seine-et-Marne, the Ile-de-France region’s largest department. In addition to Dourges and Valence, Réau is one of three sites in the French distribution network of the leading home improvement and garden product supplier. In contrast to the company’s eight regional sites and three sites with an e-commerce focus, this particular site is operated by Leroy Merlin itself rather than its logistics partners. The entire site covers an area of 72,000 m2, divided into 12 zones – around half of which have now been automated by STILL.

“Today, we store a total of 4,000 items across the warehouse, and this is soon set to increase to 8,000,” says Olivier Mangnier, Project Manager at Leroy Merlin. “By automating our internal logistics, we have been able to reduce pressure on employees, achieve our goal of zero workplace accidents as well as offer our customers shorter lead times through increased productivity.”

Finely tuned “AGV ballet”:

from receiving incoming goods to picking orders

In the goods receiving area, incoming pallets are loaded onto a conveyor system and pass through a checkpoint (checking dimensions, weight and barcode identification) before being entered into one of the 16 automated STILL EXV-SF iGo systems. Fitted with lithium-ion batteries, these AGVS can easily and conveniently be recharged at any time near their place of deployment. STILL EXV-SF iGo systems are equipped with a laser triangulation control system and transport the pallets to a pick and drop interim storage site (24,000 m2) with 40 high racks. There are 11 automated STILL MX-X iGo systems very narrow aisle trucks in operation here to handle storage and retrieval. Thanks to inductive guidance and 3D cameras, the MX-Xs can confidently navigate their way through the 90 metre long and 12 metre high aisles. After storage and retrieval, one of the automated EXV-SF iGo systems then receives the goods and feeds the conveyor, which, after a “decanting” operation (repacking of goods into storage containers), loads a shuttle with 80,000 spaces in order to pick up to 70,000 packages a day.

VR and automated shipping warehouse

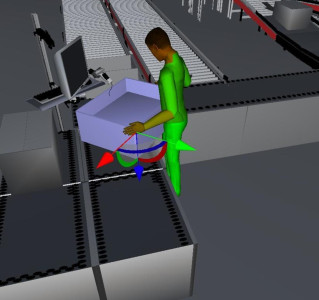

At the planning stage, Leroy Merlin used a VR (virtual reality) simulation in order to make the conveyor belt workstations as ergonomic as possible. Thanks to these optimised stations, the risk of musculoskeletal disorders is minimised as far as possible.

In the future, the automated warehouse, which consists of nine aisles on 19 levels and 171 shuttles, will be able to process 70,000 packages per day, dispatching shipments to 140 stores as well as to online customers directly.

From the analysis and testing phase to installation and integration

The task of integrating 27 AGVs should not be underestimated: “It’s not just a simple case of transporting a pallet from A to B,” explains Bruno Chambraud, Distribution Manager, Intralogistics Systems from STILL in France. “Around 3,600 pallets are moved every day, requiring the coordination of numerous material movements from one area to another. This necessitates a comprehensive flow of goods strategy that takes various load dimensions, flow of goods optimisation and the motion profiles of the AGVs into account”.

Before the actual installation, extensive testing was first carried out in one zone over a period of three months. This was designed to ensure the compatibility of all the systems: customer WMS (warehouse management system), WCS (warehouse control system), fire protection, conveyor systems from different manufacturers, IT requirements and security, etc.

“We have worked with STILL since 2006,” adds Olivier Mangnier. “Our relationship has evolved over the years, and STILL is now our sole partner for all fleets – for all our logistics sites in France.” A successful partnership: since its inauguration, there hasn’t been a single accident or interruption to operations reported in the automated area of the plant!

Individual automation solutions from STILL

Different warehouse situations require individual solutions. iGo systems offers you a perfectly coordinated combination of different automated STILL series-production trucks and corresponding technology, including the installation of all components.

Analysis, planning, implementation – put your trust in automation that meets your needs and delivers maximum efficiency by selecting the best technologies for your requirements. Various types of navigation allow the trucks to move independently through the warehouse. In this way, you can always stay flexible because all automated series-produced trucks can also be operated manually in the worst-case scenario.

The quality of the iGo systems series devices has been proven in numerous automa- tion projects. Once the tailor-made automation solution has been implemented, a professional service model guarantees that your system is available at all times.